Electronic Shelf Label Market Outlook The global electronic shelf label (ESL) market is projected to experience substantial growth, reaching a value of approximately USD 1.33 billion in 2024. The market is estimated to expand at a compound annual... More

Electronic Shelf Label Market Outlook The global electronic shelf label (ESL) market is projected to experience substantial growth, reaching a value of approximately USD 1.33 billion in 2024. The market is estimated to expand at a compound annual growth rate (CAGR) of 21.4% between 2025 and 2034, reaching an estimated value of around USD 7.59 billion by 2034. The growth of this market is driven by the increasing demand for automation, improved operational efficiency, and the growing need for better pricing strategies across the retail sector. Electronic shelf labels are becoming a prominent solution in retail environments due to their ability to provide dynamic price adjustments, better inventory management, and enhanced customer experiences. The transition from traditional paper price tags to ESL systems is being driven by the retail industry's push for digitalization and cost-effective operations. Additionally, as retailers strive for greater sustainability, the reduced need for paper and ink in ESL solutions is contributing to their growing adoption. Electronic Shelf Label Market Trends The ESL market is witnessing several key trends that are shaping its future. One of the most significant trends is the increasing adoption of e-paper and graphic e-paper displays in ESL systems. These types of displays offer improved readability, low energy consumption, and better visibility under varying lighting conditions. The shift towards e-paper is being fueled by the growing demand for energy-efficient solutions, as it helps reduce operational costs associated with traditional displays and frequent paper label replacements. Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/electronic-shelf-label-market/requestsample Another important trend is the expansion of ESL systems beyond hypermarkets and supermarkets into specialty retail stores and non-food retail stores. As the market for ESL solutions matures, more types of retailers are exploring the benefits of adopting ESL systems to streamline operations, improve pricing accuracy, and offer a seamless shopping experience. This trend is expected to further drive the adoption of ESLs in different retail sectors, such as fashion, electronics, and health & beauty. Moreover, the integration of ESL systems with advanced communication technologies, such as radio frequency (RF), near-field communication (NFC), and infrared, is enhancing the functionality of ESL systems. These technologies enable real-time updates, greater flexibility in product pricing, and improved interaction between customers and products. Retailers are increasingly leveraging these technologies to gain real-time insights into inventory, enhance customer engagement, and improve supply chain operations. Electronic Shelf Label Market Growth The ESL market is set to experience rapid growth, with a projected CAGR of 21.4% between 2025 and 2034. Several factors contribute to this growth, including the increased demand for automation in retail, enhanced inventory management solutions, and the growing emphasis on customer-centric retail experiences. As consumers become more reliant on digital solutions, there is an increasing demand for technology-driven pricing, promotion, and product display strategies. The retail sector is increasingly embracing digital signage and automation, pushing the demand for ESL systems. The market is expanding as retailers seek ways to optimize store management, reduce operational costs, and improve customer engagement. Additionally, as retailers strive to improve their sustainability practices, ESLs are being adopted as an eco-friendly alternative to traditional paper-based price tags. Another key factor driving market growth is the growing interest in integrating ESL systems with other retail technologies, such as point-of-sale (POS) systems, inventory management software, and digital signage platforms. This integration offers retailers a unified solution for store management, enabling them to make real-time pricing adjustments, track inventory, and monitor product movement seamlessly. As these technologies become more advanced and interconnected, the ESL market is expected to grow at a rapid pace. Market Segmentation Breakup by Components Displays: Displays are the most crucial component of ESL systems, as they provide the dynamic pricing and product information that is visible to customers. The demand for high-quality, energy-efficient displays is growing, driven by the adoption of e-paper and graphic e-paper technologies. Batteries: ESL systems rely on long-lasting batteries to ensure continuous operation. The development of low-energy-consuming technologies, such as e-paper, is driving the demand for batteries that offer longer life and fewer replacements. Batteries are a key component in maintaining the efficiency of ESL systems. Transceivers: Transceivers are integral for communication between ESLs and the central management system. The need for real-time communication and updates is driving innovation in transceiver technologies, particularly in wireless communication systems. Microprocessors: Microprocessors play a critical role in controlling the operation of ESL systems. As ESL solutions become more sophisticated, the demand for high-performance microprocessors capable of managing complex functions, such as real-time price updates and system integration, is increasing. Others: This category includes additional components such as software, connectors, and integration tools that facilitate the operation and management of ESL systems. Breakup by Product Liquid Crystal Displays (LCD): LCDs are commonly used in ESL systems, offering clear visibility and effective price display. While not as energy-efficient as e-paper displays, they are still widely adopted due to their low cost and reliability. E-Paper: E-paper displays are becoming the preferred choice for ESL systems due to their low energy consumption and excellent readability. The demand for e-paper-based ESL systems is increasing, particularly in stores that require long-lasting, low-maintenance displays. Graphic E-Paper: Graphic e-paper displays combine the features of traditional e-paper with the ability to show high-quality graphics and images. These displays are ideal for showcasing more detailed product information and promotions, and their adoption is increasing in sectors that require dynamic content. Segment E-Paper: Segment e-paper displays are used in simpler ESL systems that require basic pricing and product information. These displays are typically used in smaller stores and environments where only basic functionality is needed. Breakup by Display Size Less than 3 Inches: Small-sized displays are commonly used in retail environments where space is limited, such as in non-food retail stores or smaller sections of larger stores. These displays are ideal for price tags and product information. 3 to 7 Inches: Mid-sized displays are widely used in supermarkets, hypermarkets, and other large retail spaces. They provide a balance between visibility and compactness, making them ideal for displaying prices, promotions, and product details. 7 to 10 Inches: Larger displays are used in specialty stores or sections that require more detailed product information and graphics. These displays offer a larger viewing area, allowing for better communication of product features and promotions. More than 10 Inches: Displays larger than 10 inches are typically used in high-visibility areas or for advertising purposes. These displays are often used for promoting sales and providing detailed product information. Breakup by Communication Technology Radio Frequency: Radio frequency (RF) technology is commonly used for wireless communication between ESL displays and central management systems. It enables efficient and real-time updates, making it one of the most widely adopted communication technologies in ESL systems. Infrared: Infrared communication is used in ESL systems for short-range communication between displays and control systems. While not as widely adopted as RF, infrared offers advantages in specific use cases, such as in smaller stores or environments with limited communication requirements. Near-field Communication (NFC): NFC technology is increasingly being integrated into ESL systems for enabling interactive features, such as customer engagement with product displays and information. NFC allows for secure, short-range communication, which is ideal for product-related interactions in retail environments. Others: This category includes other communication technologies that are being developed or used in specific ESL applications, such as Bluetooth and Zigbee, for enhanced connectivity and functionality. Breakup by End Use Hypermarkets: Hypermarkets are among the largest users of ESL systems due to their extensive product offerings and high foot traffic. ESLs are used to improve pricing accuracy, streamline operations, and enhance the customer shopping experience. Supermarkets: Supermarkets, like hypermarkets, are increasingly adopting ESL systems to enhance efficiency, particularly for price changes, promotions, and inventory management. ESLs allow supermarkets to respond quickly to changing pricing demands and customer preferences. Non-food Retail Stores: Non-food retail stores, such as electronics and apparel stores, are adopting ESL solutions to better manage product pricing, promotions, and inventory. These stores benefit from the ability to update prices and promotions dynamically. Speciality Stores: Specialty stores that offer a narrow range of high-end or unique products are adopting ESLs to provide detailed product information and manage dynamic pricing effectively. Others: This category includes other retail environments such as convenience stores, pharmacies, and department stores, all of which are increasingly adopting ESL systems to improve operational efficiency and provide a modern shopping experience. Breakup by Region North America: North America is a leading region in the adoption of ESL systems, driven by the presence of major retailers and the growing demand for digital signage and pricing solutions. The U.S. and Canada are significant contributors to the market’s growth. Europe: Europe, with countries like the United Kingdom, Germany, and France, is a key market for ESL systems. The region’s strong retail infrastructure and demand for sustainable, digital solutions are driving the adoption of ESL technology. Asia Pacific: Asia Pacific is expected to experience the highest growth in the ESL market, with countries like China, Japan, and India showing increasing demand for electronic shelf labels. The region's large retail sector and technological advancements are driving this growth. Latin America: Latin America, including countries like Brazil and Mexico, is witnessing a growing interest in ESL systems as retail businesses look for ways to improve pricing accuracy and customer engagement. Middle East and Africa: The Middle East and Africa are emerging markets for ESL systems, driven by the modernization of retail infrastructure and the demand for digital signage solutions in countries such as Saudi Arabia, the United Arab Emirates, and South Africa. Market Key Players E Ink Holdings Inc.: E Ink is a leading provider of e-paper technology for ESL systems. The company’s innovations in low-power, high-visibility displays have made it a key player in the global ESL market. Pricer AB: Based in Sweden, Pricer AB is a major player in the ESL market, offering a wide range of electronic shelf labels for retail environments. The company focuses on providing cost-effective and energy-efficient solutions. Displaydata Limited: Displaydata is a UK-based company that specializes in the development of ESL systems. The company’s products are used in retail environments to improve pricing, promotions, and inventory management. troniTAG GmbH: troniTAG is a German company that designs and manufactures ESL solutions. The company focuses on providing high-quality electronic shelf labels for supermarkets, hypermarkets, and specialty stores. SES-imagotag Group: SES-imagotag is a global leader in digital labeling solutions, providing ESL systems for retailers worldwide. The company offers innovative products that enhance pricing accuracy and customer engagement in retail environments. Others: Other notable players in the ESL market include SoluM, Pricer, and LG Innotek, all of which contribute to the expansion of the global electronic shelf label industry through innovation and customer-centric solutions. Media Contact: Company Name: Claight CorporationContact Person: Eren smith, Corporate Sales Specialist – U.S.A.Email: sales@expertmarketresearch.comToll Free Number: +1-415-325-5166 | +44-702-402-5790Address: 30 North Gould Street, Sheridan, WY 82801, USAWebsite: https://www.expertmarketresearch.com Less

Consumer Goods and Services

Europe Cocoa Market Outlook The Europe cocoa market was valued at USD 9.89 billion in 2024 and is projected to grow at a CAGR of 4.20% between 2025 and 2034, reaching USD 14.45 billion by 2034. The growing demand for cocoa-based products across... More

Europe Cocoa Market Outlook The Europe cocoa market was valued at USD 9.89 billion in 2024 and is projected to grow at a CAGR of 4.20% between 2025 and 2034, reaching USD 14.45 billion by 2034. The growing demand for cocoa-based products across food and beverage, cosmetics, and pharmaceutical industries is driving market expansion. Europe remains a key consumer and processor of cocoa, with strong demand for premium chocolate, confectionery, and cocoa-based health products. The increasing focus on sustainable cocoa sourcing is influencing industry dynamics, with major chocolate manufacturers committing to ethical and responsible supply chains. Rising consumer preference for organic and fair-trade cocoa is reshaping procurement strategies, leading to the expansion of certified cocoa production. Additionally, the growing popularity of cocoa-infused skincare and pharmaceutical products is broadening the application of cocoa beyond traditional confectionery. Technological advancements in cocoa processing, improved fermentation techniques, and innovative product formulations are further supporting market growth. The shift towards healthier chocolate variants with reduced sugar and higher cocoa content is gaining traction among health-conscious consumers. With strong market demand and evolving industry trends, the Europe cocoa market is poised for steady growth over the coming decade. Get a Free Sample Report with Table of Contents@https://www.expertmarketresearch.com/reports/europe-cocoa-market/requestsample Europe Cocoa Market Trends The Europe cocoa market is witnessing significant transformations driven by evolving consumer preferences and industry advancements. One of the key trends is the rising demand for premium and artisanal chocolates. Consumers are increasingly seeking high-quality chocolates with unique flavors, organic ingredients, and higher cocoa content, fueling demand for specialty cocoa products. Another prominent trend is the growing focus on sustainability and ethical sourcing. Leading cocoa producers and chocolate manufacturers are investing in sustainability initiatives to ensure fair wages for farmers, prevent deforestation, and promote eco-friendly farming practices. Certifications such as Rainforest Alliance, UTZ, and Fairtrade are gaining popularity as consumers prioritize ethically sourced cocoa. The expansion of cocoa applications beyond food and beverages is another emerging trend. Cocoa butter and cocoa extracts are widely used in cosmetics and pharmaceuticals due to their antioxidant and skin-nourishing properties. The demand for cocoa-based skincare products is increasing, particularly in natural and organic beauty segments. The rise of functional and healthier chocolate products is influencing the market landscape. Manufacturers are introducing dark chocolate variants with higher flavonoid content, reduced sugar, and added functional ingredients such as probiotics and superfoods to cater to health-conscious consumers. The trend of using cocoa in plant-based and dairy-free chocolate alternatives is also growing. The advancement of cocoa processing technologies is enhancing product quality and efficiency. Improved fermentation, drying, and roasting techniques are optimizing flavor profiles, while automated processing systems are boosting production capacity. The adoption of blockchain and digital tracking systems in cocoa supply chains is improving transparency and traceability. Europe Cocoa Market Growth The growth of the Europe cocoa market is driven by increasing chocolate consumption, rising demand for cocoa-based cosmetics and pharmaceuticals, and advancements in processing technologies. The food and beverage sector remains the largest consumer of cocoa, with chocolate manufacturers, bakeries, and confectionery brands expanding their product portfolios to meet growing consumer demand. The popularity of premium and craft chocolates is further driving sales in this segment. The cosmetics and pharmaceuticals industry is experiencing increased demand for cocoa derivatives, particularly cocoa butter, which is widely used in skincare, lip balms, and anti-aging products. The antioxidant-rich properties of cocoa make it a valuable ingredient in health and wellness formulations, leading to its growing application in nutraceuticals and dietary supplements. Sustainability initiatives and ethical sourcing practices are playing a crucial role in market expansion. Leading cocoa producers are investing in farmer training programs, regenerative agriculture, and supply chain transparency to enhance cocoa quality and sustainability. The rise of direct trade cocoa sourcing, where brands purchase directly from farmers, is fostering fair trade practices and improving quality control. Government regulations and industry standards supporting sustainable cocoa production are also contributing to market growth. European regulatory bodies are promoting deforestation-free cocoa sourcing and setting guidelines for fair labor practices. The increasing adoption of these standards is shaping procurement strategies and influencing consumer purchasing decisions. The growing demand for cocoa powder and cocoa liquor in the beverage industry is another significant growth factor. Cocoa-based drinks, including hot chocolate, flavored milk, and cocoa-infused coffee blends, are gaining popularity among consumers, driving higher demand for processed cocoa ingredients. The expansion of dairy-free and vegan cocoa beverages is further strengthening market growth. Market Segmentation Breakup by Type: Cocoa Butter – Widely used in chocolate manufacturing, cosmetics, and pharmaceutical products. The demand for cocoa butter in skincare and organic beauty products is increasing. Cocoa Powder – Used in beverages, bakery products, and confectionery. The growth of the bakery and functional food industry is driving demand for high-quality cocoa powder. Cocoa Liquor – The base ingredient for chocolate production, essential for premium and artisanal chocolate manufacturing. The expansion of craft chocolate brands is boosting cocoa liquor consumption. Breakup by Application: Food and Beverages – The largest segment, including chocolate, bakery, confectionery, dairy products, and beverages. Premium and organic cocoa products are gaining popularity in this category. Cosmetics and Pharmaceuticals – Cocoa butter is widely used in skincare, lip care, and anti-aging products, while cocoa extracts are utilized in pharmaceuticals for their antioxidant benefits. Others – Includes cocoa applications in pet food, nutraceuticals, and dietary supplements. The rise in functional food formulations is expanding the use of cocoa in these sectors. Breakup by Region: Germany – One of the largest consumers of cocoa in Europe, with a strong presence of chocolate manufacturers and confectionery brands. The demand for sustainable and organic cocoa is increasing. United Kingdom – The market is driven by high chocolate consumption, the expansion of premium and craft chocolate brands, and the growing preference for ethical cocoa sourcing. France – Known for its luxury chocolate market, France is witnessing rising demand for artisanal and high-cocoa-content chocolates. The cosmetics industry also contributes to cocoa butter demand. Italy – The growth of the bakery and confectionery sector is fueling demand for cocoa powder and cocoa liquor. The country’s focus on high-quality chocolate production supports market expansion. Others – Includes Spain, the Netherlands, Belgium, and other European nations with significant cocoa consumption and processing industries. These countries are adopting sustainable cocoa practices to meet consumer demand. Market Key Players Cargill Inc. – A leading global supplier of cocoa and chocolate products, committed to sustainable sourcing and high-quality cocoa processing. Barry Callebaut AG – One of the world’s largest cocoa processors and chocolate manufacturers, focusing on innovation and sustainability. Nestlé S.A. – A key player in the chocolate and confectionery market, integrating ethical cocoa sourcing into its supply chain. Mondelez International, Inc. – The company behind brands like Cadbury and Milka, investing in sustainable cocoa farming and fair-trade practices. BASF SE – Specializing in cocoa-based ingredients for cosmetics and pharmaceuticals, enhancing product formulations with cocoa extracts. Buhler AG – A technology provider for cocoa processing, offering advanced solutions for fermentation, roasting, and grinding. Ferrero International S.A. – Known for premium chocolate brands like Ferrero Rocher, emphasizing sustainable cocoa sourcing and ethical supply chain management. Mars Inc. – A major chocolate manufacturer focusing on fair-trade cocoa sourcing and environmentally responsible production methods. Forever Cacao – A craft chocolate brand emphasizing organic and direct-trade cocoa, catering to the growing demand for premium chocolate. GCB Cocoa UK Ltd. – A significant player in the UK cocoa processing industry, supplying high-quality cocoa ingredients to food and beverage manufacturers. Others – Several regional and global companies are contributing to the growth of the European cocoa market by adopting innovative processing techniques and sustainable sourcing initiatives. Media Contact: Company Name: Claight CorporationContact Person: Eren smith, Corporate Sales Specialist – U.S.A.Email: sales@expertmarketresearch.comToll Free Number: +1-415-325-5166 | +44-702-402-5790Address: 30 North Gould Street, Sheridan, WY 82801, USAWebsite: https://www.expertmarketresearch.com Less

Agriculture and Farming

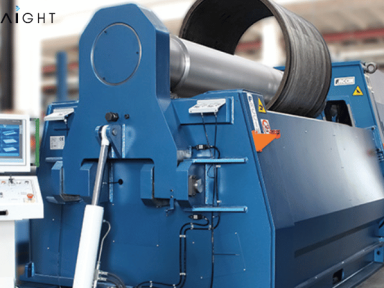

Metal Forming Machine Tools Market Outlook The global metal forming machine tools market is expected to grow at a compound annual growth rate (CAGR) of 4% between 2025 and 2034. The increasing demand for high-quality, precision-engineered... More

Metal Forming Machine Tools Market Outlook The global metal forming machine tools market is expected to grow at a compound annual growth rate (CAGR) of 4% between 2025 and 2034. The increasing demand for high-quality, precision-engineered products in industries such as automotive, general machinery, and precision engineering is driving the market's expansion. Metal forming machine tools are essential for the production of various components, including gears, brackets, and frames, contributing to the growth of key industries. The market is benefiting from advancements in technology, including the increasing adoption of Computerized Numerical Control (CNC) systems, which enhance precision, reduce human errors, and allow for automated operations. Additionally, the demand for metal forming machine tools is also growing due to the rise in infrastructure development, industrial manufacturing, and transportation machinery across global markets. Metal Forming Machine Tools Market Trends Several key trends are influencing the growth of the global metal forming machine tools market: Adoption of Advanced CNC Technology: CNC machines are becoming increasingly popular in the metal forming process due to their ability to produce precise and complex parts quickly. These machines are highly automated and allow for increased production efficiency, driving their demand across industries such as automotive, aerospace, and general manufacturing. The trend towards automation is also reducing labor costs and enhancing productivity. Integration of IoT and AI in Metal Forming Machines: The integration of the Internet of Things (IoT) and Artificial Intelligence (AI) into metal forming machine tools is revolutionizing the industry. These technologies enable real-time monitoring, predictive maintenance, and data analysis, allowing manufacturers to optimize performance, prevent downtime, and improve quality control. AI-powered systems also allow for faster decision-making and enhance machine operation. Shift Towards Sustainable and Energy-Efficient Machines: As industries move toward more sustainable production methods, there is a growing demand for energy-efficient metal forming machines that minimize waste, lower energy consumption, and reduce carbon footprints. Manufacturers are increasingly investing in energy-efficient solutions that reduce operational costs and meet environmental standards. Rise in Demand for Customization and Flexibility: The growing need for customized products, especially in industries like automotive and aerospace, is driving the demand for versatile metal forming machine tools. Manufacturers are looking for flexible solutions that can handle different materials and production volumes, making customizability a key factor in the growth of the market. Increased Focus on Precision and Quality Control: Industries such as aerospace, automotive, and electronics demand high-precision components. To meet these requirements, metal forming machines are increasingly equipped with advanced features that allow for greater accuracy in the manufacturing process. As a result, quality control and precision are top priorities for companies investing in metal forming technologies. Expansion of Manufacturing Facilities in Emerging Markets: The growing manufacturing sector in emerging markets, such as Asia-Pacific and Latin America, is creating new opportunities for metal forming machine tools. Countries like China, India, Brazil, and Mexico are investing heavily in manufacturing infrastructure, leading to an increase in demand for high-quality metal forming machines. Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/metal-forming-machine-tools-market/requestsample Metal Forming Machine Tools Market Growth The growth of the global metal forming machine tools market is fueled by several key drivers: Rising Industrialization and Infrastructure Development: With the continued industrialization and infrastructure development in emerging economies, the demand for metal forming machine tools is expected to rise significantly. As these markets grow, there is a higher need for machinery that can produce complex metal components for construction, transportation, and consumer products. Automotive Industry Demand: The automotive industry is one of the largest consumers of metal forming machine tools, particularly in the production of parts such as body panels, brackets, and frames. As global vehicle production increases, especially with the rise in electric vehicle (EV) manufacturing, the demand for advanced metal forming machinery is expected to continue its upward trajectory. Technological Advancements in Metal Forming: Innovations in machine tools, such as increased precision, faster production speeds, and the ability to work with more materials, are driving the growth of the market. These technological advancements help manufacturers improve efficiency and reduce costs, making metal forming processes more cost-effective and scalable. Shift Toward Automation and Robotics: Automation in manufacturing, including the use of robotics in metal forming, is helping industries meet higher production demands while improving consistency and reducing human error. Automation is becoming a significant trend in the metal forming machine tools market, with manufacturers investing in robotic systems to handle tasks such as loading, unloading, and material handling. Growing Need for Aerospace Components: The aerospace industry’s demand for precision-engineered metal components is driving growth in the metal forming market. The use of advanced metal forming machines to create lightweight, high-performance materials for aircraft is contributing to the expansion of the market. Increased Focus on Recycling and Sustainability: Recycling scrap metal and reusing materials are becoming increasingly important in many manufacturing processes, particularly in industries like automotive and construction. The need for metal forming machines that can process recycled materials is helping drive market growth as manufacturers seek sustainable production methods. Market Segmentation The global metal forming machine tools market is segmented by technology, product type, application, and region, each playing a crucial role in the market's development. Breakup by Technology Computerized Numerical Control (CNC): CNC machines are increasingly in demand due to their precision, efficiency, and automation capabilities. These machines are essential for industries that require high-precision components and fast production rates, such as automotive, aerospace, and general machinery manufacturing. Conventional: Conventional metal forming machines are still widely used in applications where cost-effective, low-volume production is required. While they may lack the precision and automation of CNC machines, they remain popular in smaller, traditional manufacturing environments. Breakup by Product Type Rolling Mill Machines: Rolling mills are used to process metal materials into thinner sheets, strips, or plates. They are commonly used in steel and aluminum production and are critical for the automotive and construction industries. Bending Machines: Bending machines are used to create bends or curves in metal sheets or rods. These machines are essential in industries like automotive and general machinery for producing parts such as frames and brackets. Hydraulic Presses: Hydraulic presses use hydraulic force to shape or form metal materials. They are widely used in industries such as automotive, aerospace, and general manufacturing to create complex shapes and components. Mechanical Presses: Mechanical presses use mechanical energy to form or shape metal components. These presses are commonly used for high-speed, high-volume production, particularly in automotive manufacturing. Shearing Machines: Shearing machines are used to cut large metal sheets or plates into smaller sizes. They are widely used in industries such as automotive, aerospace, and construction. Forging Machines: Forging machines are used to shape metal by applying compressive force. These machines are essential in industries that require high-strength components, such as aerospace, automotive, and defense. Wire Forming Machines: Wire forming machines are used to shape metal wires into specific shapes, such as coils or springs. These machines are critical in industries like automotive, electronics, and consumer goods manufacturing. Others: This category includes machines such as punch presses, stretch-forming machines, and other specialized equipment used in metal forming processes. Breakup by Application Automotive: The automotive industry is one of the largest consumers of metal forming machines, using them to produce parts such as body panels, frames, and engine components. The growing demand for electric vehicles (EVs) is further boosting the demand for precision metal forming machines. General Machinery: Metal forming machines are widely used in the general machinery industry to produce a variety of components, including gears, brackets, and structural parts. The demand for such components is increasing with industrial expansion worldwide. Precision Engineering: The precision engineering sector requires high-precision parts, such as gears and shafts, which are produced using advanced metal forming technologies. The growth of industries like aerospace and robotics is driving this demand. Transport Machinery: Transport machinery, including components for trains, ships, and heavy vehicles, relies on metal forming machines for the production of robust, durable parts. The expansion of the transport sector is driving demand for metal forming tools. Others: Other industries using metal forming machines include defense, energy, and electrical industries, where components such as military equipment, turbines, and electrical panels are formed. Breakup by Region North America: The North American market for metal forming machine tools is driven by strong industrial sectors such as automotive, aerospace, and general manufacturing. The United States and Canada are the key markets in this region. Europe: Europe is a key market, with countries like Germany, Italy, and the United Kingdom leading the demand for metal forming machines, especially in the automotive and machinery manufacturing industries. Asia Pacific: The Asia Pacific region is witnessing rapid growth in the metal forming machine tools market due to the industrialization of emerging economies such as China, India, and Japan. These countries are investing heavily in manufacturing infrastructure, further driving market demand. Latin America: The Latin American market is growing steadily, particularly in countries like Brazil and Mexico, where manufacturing industries are expanding and requiring advanced metal forming tools. Middle East and Africa: The Middle East and Africa region is experiencing steady demand for metal forming machines, driven by infrastructure development, particularly in countries like Saudi Arabia and the UAE. Market Key Players The global metal forming machine tools market is highly competitive, with several prominent players dominating the landscape. Some key players include: Mitsubishi Material Corporation: Mitsubishi is a leading manufacturer of metal forming machines, providing advanced solutions for automotive, aerospace, and general manufacturing industries. Amada Co., Ltd.: Amada offers a wide range of metal forming machines, including CNC presses, laser cutters, and punch presses, serving industries such as automotive, aerospace, and electronics. Komatsu Ltd.: Komatsu is a global leader in the production of heavy machinery, including metal forming tools and equipment used in various manufacturing sectors. Machine Tools (India) Limited: This Indian company manufactures metal forming machinery used in industries such as automotive and general manufacturing. Schuler AG: Schuler specializes in high-performance metal forming machines and systems, catering to industries like automotive, aerospace, and electronics. Read More Trending Blogs: Top 15 Sugar Companies Worldwide | Leading Manufacturers & Brands Top 4 ATM Service Companies Worldwide | Best Providers in 2025 Top 6 Companies Dominating the Global Telescopic Handler Market Media Contact: Company Name: Claight CorporationContact Person: Eren smith, Corporate Sales Specialist – U.S.A.Email: sales@expertmarketresearch.comToll Free Number: +1-415-325-5166 | +44-702-402-5790Address: 30 North Gould Street, Sheridan, WY 82801, USAWebsite: https://www.expertmarketresearch.com Less

Manufacturing

Brazil Flavours Market Outlook The Brazil flavours market size is expected to experience significant growth during the forecast period of 2025-2034, with a compound annual growth rate (CAGR) of 6.50%. This growth can be attributed to several... More

Brazil Flavours Market Outlook The Brazil flavours market size is expected to experience significant growth during the forecast period of 2025-2034, with a compound annual growth rate (CAGR) of 6.50%. This growth can be attributed to several factors, including the increasing demand for innovative and diverse flavours in the food and beverage industry, rising consumer preference for natural and organic ingredients, and the continuous expansion of various sectors, including dairy, bakery, and beverages. As consumer tastes evolve and the demand for customised, authentic flavours continues to rise, Brazil’s flavouring industry is witnessing substantial growth. The market is benefiting from innovations in flavouring technologies, which are enabling manufacturers to create unique products that cater to the changing preferences of consumers. Additionally, growing awareness about healthy eating and natural ingredients is driving the shift towards natural flavours, thereby enhancing market growth. Brazil Flavours Market Trends The Brazilian flavours market is experiencing several trends that are reshaping the industry. These trends are driven by consumer preferences for natural, organic, and sustainable ingredients, as well as advancements in flavour technology. Notable trends include: Rising Demand for Natural Flavours: There is a growing consumer demand for natural and organic flavours, driven by the increasing awareness of health and wellness. Natural flavours, derived from fruits, spices, and herbs, are being preferred over artificial flavouring substances due to their perceived health benefits and clean label appeal. Shift Towards Clean Labels: Consumers are increasingly opting for products with clean and simple ingredient lists, avoiding artificial additives. This trend is driving the demand for natural flavouring substances, which are perceived as safer and healthier. Clean label products are gaining popularity in Brazil, especially in the food and beverage sectors. Innovation in Flavouring Solutions: Manufacturers are investing in innovative flavouring technologies to develop new and exotic flavours that cater to Brazilian consumers’ evolving tastes. From tropical fruit-based flavours to regional specialities, flavour companies are continually expanding their portfolios to provide unique and exciting flavour experiences. Growth of Functional Foods and Beverages: With the growing interest in health and wellness, functional foods and beverages are becoming increasingly popular in Brazil. Flavour manufacturers are responding to this demand by developing flavours for products that offer additional health benefits, such as fortified beverages, protein-rich snacks, and functional dairy products. Adoption of Clean and Sustainable Sourcing: Sustainability is becoming a key factor in flavour sourcing. Consumers are more conscious of the environmental impact of their purchases, which is driving flavour companies to adopt sustainable practices, such as sourcing ingredients from renewable sources and minimising waste in production processes. Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/brazil-flavours-market/requestsample Brazil Flavours Market Growth The Brazil flavours market is expected to grow at a CAGR of 6.50% from 2025 to 2034. Several factors are contributing to this growth: Consumer Preference for Unique and Exotic Flavours: The Brazilian consumer market is known for its diverse tastes and preference for regional and exotic flavours. This demand for unique flavour experiences is driving growth in the flavours market, particularly in sectors like beverages, snacks, and confectionery. Expansion of the Food and Beverage Industry: The food and beverage industry in Brazil is undergoing rapid growth, with increasing consumption of ready-to-eat meals, snacks, and beverages. This expansion is creating a significant demand for innovative and diverse flavouring solutions, particularly for beverages, bakery, dairy, and frozen desserts. Growth of the Health-Conscious Consumer Segment: With the rise of the health-conscious consumer segment, there is an increasing demand for healthier, natural flavour options in food and beverages. This trend is expected to drive the growth of natural and organic flavouring substances, which are seen as better alternatives to artificial ingredients. Increasing Export Opportunities: Brazil is a major producer of agricultural products, including tropical fruits, which are used in flavour formulations. The growing export opportunities for Brazilian food products are helping to drive demand for local flavours, contributing to the overall growth of the flavouring market in the country. Technological Advancements: Flavour companies are investing in advanced technologies, such as encapsulation techniques and microencapsulation, to improve the shelf life and stability of natural flavours. These technological advancements are expected to further fuel the growth of the Brazilian flavours market. Market Segmentation The Brazilian flavours market can be segmented based on flavouring agent, form, and application. These segments provide insights into consumer preferences, key drivers of growth, and emerging opportunities within the market. 1. Breakup by Flavouring Agent: Nature Identical Flavouring Substance: Nature identical flavouring substances are artificial compounds that replicate the taste of natural ingredients. These substances are used to create consistent flavours in products and are expected to see steady demand, particularly in applications where cost efficiency is a major consideration. Artificial Flavouring Substance: Artificial flavouring substances are widely used in the food and beverage industry to enhance the taste of products at a lower cost compared to natural flavours. While the demand for artificial flavouring substances is still significant, it is facing increasing competition from natural alternatives due to growing consumer preferences for cleaner labels and healthier products. Natural Flavours: Natural flavours are derived from fruits, vegetables, herbs, and other plant-based ingredients, and they are becoming increasingly popular due to the rising consumer demand for healthier, more sustainable products. The natural flavours segment is expected to grow at the fastest pace during the forecast period, driven by the clean label trend and increased awareness of the benefits of natural ingredients. 2. Breakup by Form: Liquid: Liquid flavours are widely used in the food and beverage industry due to their ease of incorporation into products such as beverages, sauces, and confectionery. Liquid flavours are expected to dominate the market due to their versatility and convenience in product formulations. Dry: Dry flavours are used in applications such as bakery products, snacks, and seasonings. As dry flavours offer longer shelf life and ease of storage, they are likely to see increased adoption in the food processing industry, especially in savoury and snack products. 3. Breakup by Application: Beverages: The beverages segment is one of the largest consumers of flavours in Brazil, driven by the increasing popularity of soft drinks, juices, energy drinks, and alcoholic beverages. The demand for innovative and exotic flavours in beverages, such as tropical fruit-based blends, is expected to drive market growth in this segment. Bakery and Confectionary Products: Bakery and confectionery products are a significant application for flavours in Brazil. The demand for sweet and exotic flavours, such as chocolate, vanilla, and tropical fruit-based flavours, is increasing in this sector, as consumer preferences continue to evolve towards more indulgent and novel taste experiences. Dairy and Frozen Desserts: Dairy products, including ice cream, yogurt, and flavoured milk, are essential applications for flavours in Brazil. The growth of the dairy and frozen desserts sector, along with the increasing popularity of healthier frozen dessert options, is driving the demand for both natural and nature identical flavours. Savouries and Snacks: Savoury snacks, including chips, crackers, and ready-to-eat meals, represent a growing application for flavours in Brazil. As consumers seek more diverse and bold flavours in snack products, the demand for savoury flavours is expected to rise, particularly in processed foods. Others: Other applications for flavours include sauces, dressings, and seasonings. As the demand for convenience foods continues to grow, the use of flavours in these categories is expected to contribute to the overall market growth. Market Key Players Several key players dominate the Brazilian flavours market, offering a wide range of flavouring solutions across various applications. These companies are known for their innovative approaches to flavour development, sustainability initiatives, and strong market presence. Key market players include: Givaudan SA Firmenich SA International Flavors & Fragrances Inc. Archer Daniels Midland Company Synergy Flavors Inc DUAS RODAS Others These companies are at the forefront of developing innovative and sustainable flavouring solutions, responding to consumer demands for cleaner labels, healthier options, and unique taste experiences. Their continued investment in research and development, along with their global presence, positions them well for capturing opportunities in the growing Brazilian flavours market. Read More Trending Blogs: Top 7 Companies Leading the Asia-Pacific Dairy Market | 2025 Insights Top 10 Battery Recycling Companies Worldwide | Leading Market Players Top 7 Digital Map Companies | Leading Global Market Players in 2025 Media Contact: Company Name: Claight CorporationContact Person: Eren smith, Corporate Sales Specialist – U.S.A.Email: sales@expertmarketresearch.comToll Free Number: +1-415-325-5166 | +44-702-402-5790Address: 30 North Gould Street, Sheridan, WY 82801, USAWebsite: https://www.expertmarketresearch.com Less

Chemicals and Materials